In order to continue to make the mower special and strong, the company willmove to a new factory at the end of September. Welcome to guide.

2016 The company has developed a semi-automated assembly line. In response to practical problems such as difficulty in recruiting workers and unskilled new workers, the company has developed a semi-automatic lawn mower assembly production line. The product quality of the key positions is guaranteed by the machine.

In 2013, it encountered a flood in a hundred years, a BS engine with a value of more than 10 million, a finished product of 4 million blow dryers, a finished product of 7 million lawn mowers, and a library with a value of 6 million. All of them were soaked in floods. ,scrapped. The factory was damaged by floods and the machinery and equipment were damaged. Under this circumstance, all the great players worked hard and strictly abide by the contract. There was no delay in the delivery of orders, no quality accidents occurred, and they were widely praised by customers and peers.

In this year, we boarded the commanding heights of the industry and presided over and drafted five national standards for lawn mowers. So far, a total of 7 national standards have been drafted and drafted, and 4 national standards have been drafted.

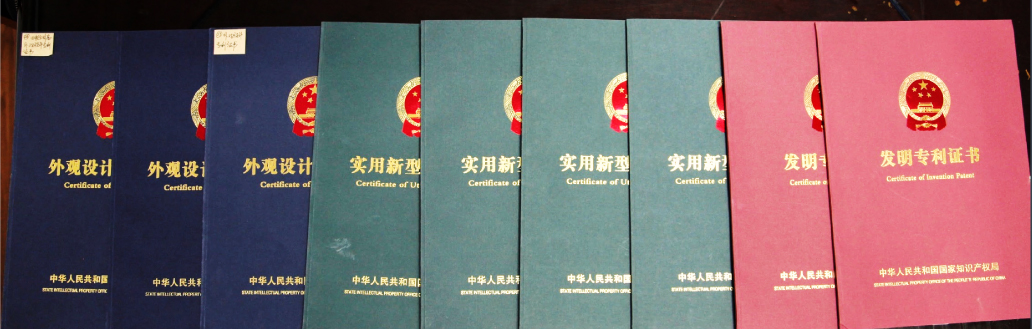

We have gathered outstanding technical talents in the industry and applied for a number of lawn mower patents during the year. So far we have more than 60 utility model patents, more than 20 appearance patents and 6 invention patents.

The company has significantly adjusted the supplier system and improved the supplier system to deliver orders on time, quantity and on time. In order to ensure quality, all accessories are produced by professional suppliers.

The company moved to the Yangming West Road plant and the scale of the factory expanded. The annual production of electric lawn mowers is 50,000 units and gasoline lawn mowers are 60,000 units. And the factory passed the ISO quality assurance system.

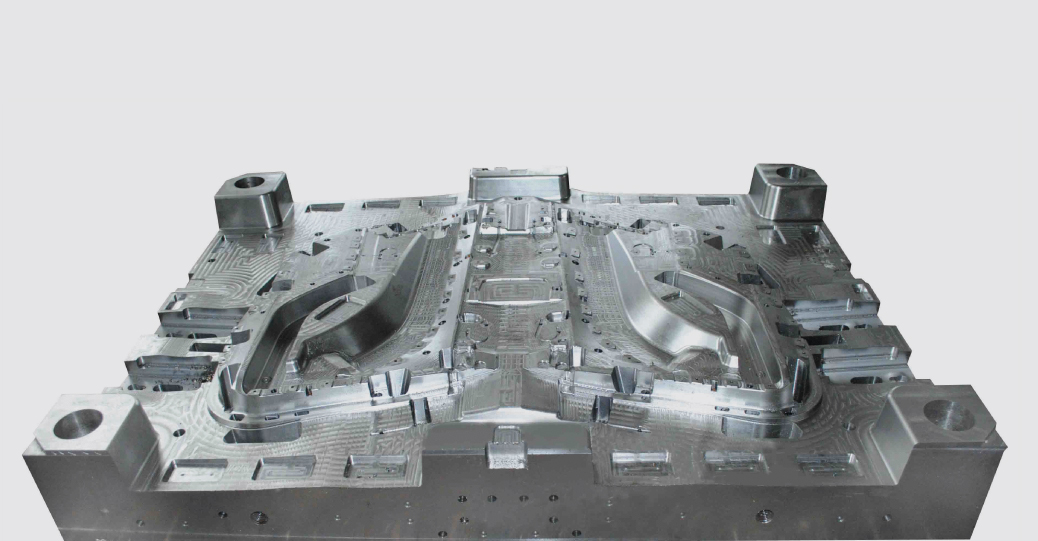

Mr. Wu, the current chairman of the company, is formally controlled. Mr. Wu was originally a teacher. He founded the mold manufacturing factory after the reform and opening up and served as the vice president of Yuyao Mould Association. Good at product design and development. His motto is a sentimental and righteous, and the motto of doing things is well-formed. And attach great importance to credibility.

Ningbo Daye Power Company acquired the lawn mower project of Shanghai Xingtehao Company. The original mower Intellectual property, all related technologies and materials and supporting supplier system, mold production equipment, testing equipment, sales channels and senior management All personnel were transferred to Ningbo Daye. Since then, Ningbo Daye has been manufacturing and manufacturing lawn mowers. At that time, the products were sold to Auchan and Kingfisher.

In the 1990s, the European lawn mower industry was transferred to China. In 1998, Shanghai Xingtehao began to combine the advanced technology of Europe to produce lawn mowers. Ningbo Daye Power Machinery Co., Ltd. was a famous mold manufacturing enterprise in Ningbo at that time, and participated in the research and development and mold manufacturing of lawn mowers in Shanghai Xingtehao.